Oil Sampling Method: Vacuum Pump

Low-cost, simple and one of the most commonly used methods of oil sampling

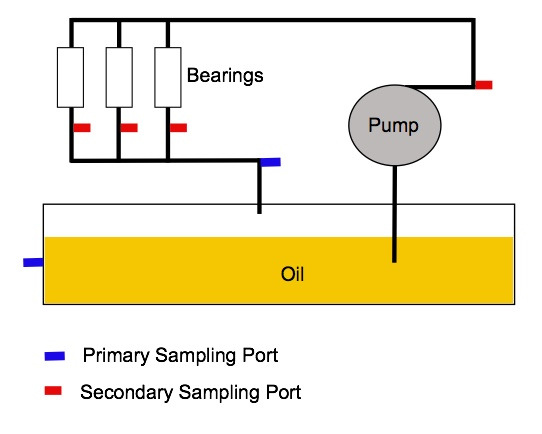

Vacuum pumps can be used with dipstick retaining tubes and other non-pressurized system points, such as installed sampling valves, oil level plugs, oil fill ports, and radiator caps

A tube is inserted through a fill port or dip stick port and sample is taken about midway into the oil level and should be drawn at the same level each time

Tubing must be inserted carefully to avoid scraping debris along sides of the casing or other interior surfaces

Quick-connect sampling valve can be installed to improve sampling

A large volume of oil is required for proper flushing to obtain a representative sample (5-10:1 ratio)

Systems are often shut down for this method, requiring samples to be taken as quickly as possible to minimize the effects