Please Chill while we are sending your message !

Wilfred Laboratories is one of the leading Oil Condition Monitoring (OCM) and Used Oil analysis (UOA) testing’s service provider with NABL Accreditation. Wilfred Laboratory has obtained NABL accreditation for Chemical testing discipline for more than 100 tests scope under Oils, Coolants & Greases. All testing’s are carried out in accordance with ASTM or IS standards and all equipment’s are calibrated by NABL Accredited agencies to maintain accuracy in our results. Wilfred Laboratory is committed to offer “Quality Services at Affordable Rates”.

get more info

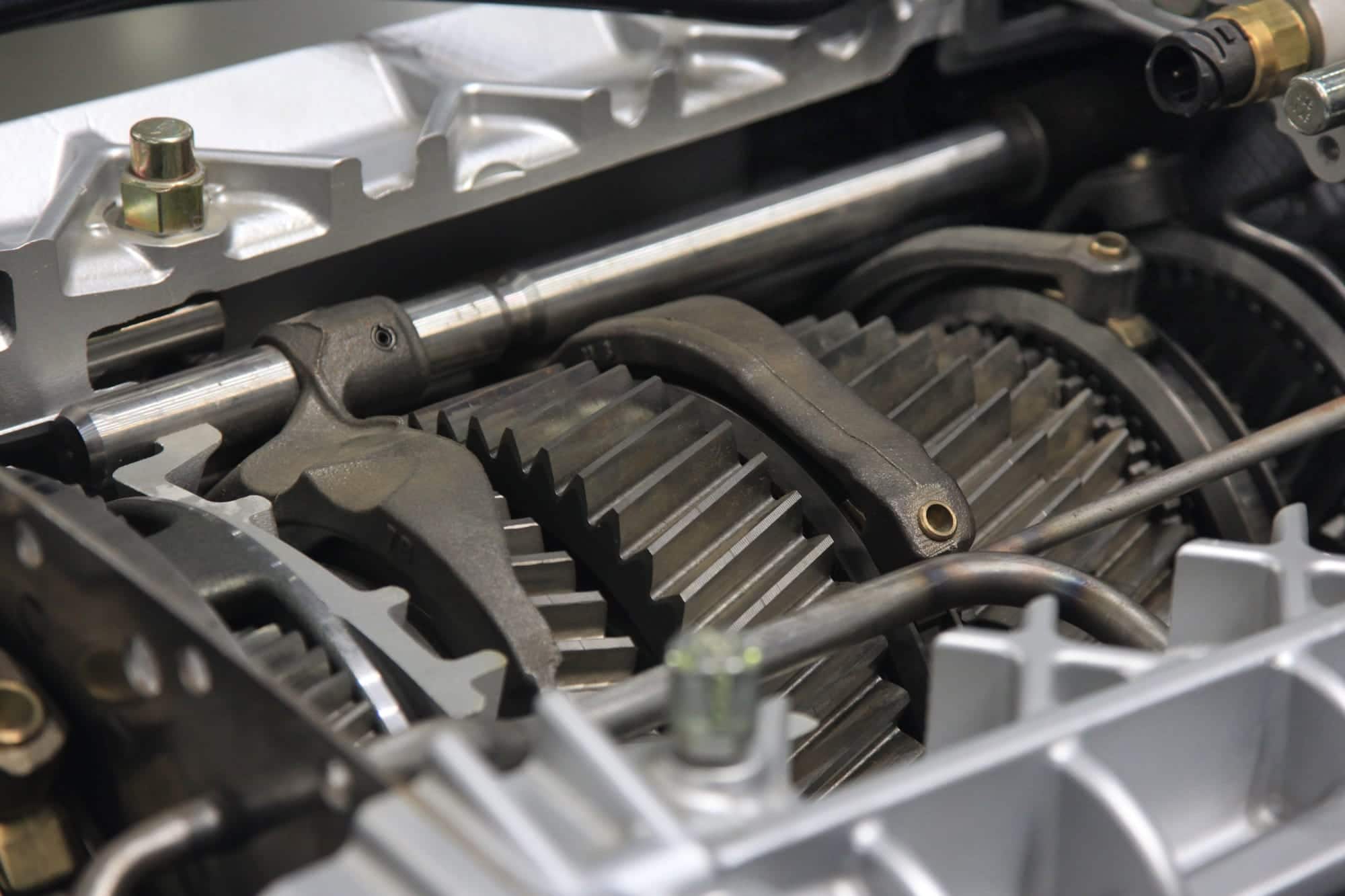

Testing the oil in used gearboxes is an important part of maintenance to make sure that gearboxes work well and last a long time. During this testing, the condition of the gearbox's lubricant is examined for signs of wear, contamination, or degradation. The most important aspects of testing used gearbox oil are:

By ensuring that the oil is performing as required, regular testing of used gearbox oil helps to predict potential failures, plan maintenance schedules, and extend the gearbox's lifespan.

Condition Monitoring and Grease Testing Grease testing is an essential component of industrial machinery condition monitoring. Grease testing aims to evaluate the health and performance of lubricating grease, which is essential for safeguarding gears, bearings, and other mechanical parts. In condition monitoring, important aspects of grease testing include:

As part of a condition monitoring program, grease testing on a regular basis helps predict potential machinery failures, optimize lubrication schedules, and extend the life of crucial components. It prevents costly downtime and repairs while also ensuring that the grease continues to function properly.

In a variety of industries, where coolant plays a crucial role in regulating temperatures, preventing corrosion, and maintaining the efficiency of machinery and engines, coolant testing is an essential part of maintenance and condition monitoring. Testing the coolant on a regular basis contributes to the maintenance of machinery, the prevention of breakdowns, and the extension of its useful life.

Regular coolant testing aids in the prevention of equipment failures caused by contamination, overheating, or corrosion. It ensures that the cooling system offers adequate protection under a variety of operating conditions, helps machinery run more effectively, and cuts down on costs associated with maintenance.

Testing of Used Engine Oil in Condition Monitoring Testing is an essential component of engine condition monitoring because it aids in determining the state of the oil and overall health of the engine. By breaking down the properties of utilized motor oil, potential issues can be distinguished early, considering opportune support and staying away from exorbitant motor disappointments.

As part of condition monitoring, regular testing of used engine oil enables the early detection of wear, contamination, and oil degradation. Planning maintenance tasks, extending engine life, and ensuring optimal engine performance are all made easier by this tool.

Testing used hydraulic oil is an important part of condition monitoring, especially in hydraulic systems where the oil is important for power transmission, lubrication, and cooling. The condition of used hydraulic oil can be assessed, potential issues in the hydraulic system can be identified, and failures can be avoided with the assistance of testing.

As part of a condition monitoring program, used hydraulic oil testing on a regular basis helps identify early signs of wear, contamination, and oil degradation. This proactive approach prolongs the oil's and machinery's lifespan, reduces downtime, and ensures the reliability of hydraulic systems.

The transmission system of a vehicle relies on transmission oil, also known as transmission fluid, for lubrication, cooling, and hydraulic pressure. One important part of condition monitoring is keeping an eye on the condition of the transmission oil. This helps to make sure the transmission runs smoothly and avoid expensive repairs.

Standard transmission oil testing as a feature of condition observing aides in recognizing early indications of wear, pollution, and oil debasement. This proactive approach ensures that the transmission system functions effectively, lowers the likelihood of unanticipated breakdowns, and extends the transmission's overall lifespan.

Compressor oil provides lubrication, cooling, and sealing, all of which are necessary for the effective operation of compressors. In condition monitoring, it is important to test the compressor oil on a regular basis to make sure the oil and the compressor system are healthy. This proactive approach extends the compressor's lifespan, saves money on maintenance, and helps prevent equipment failures.

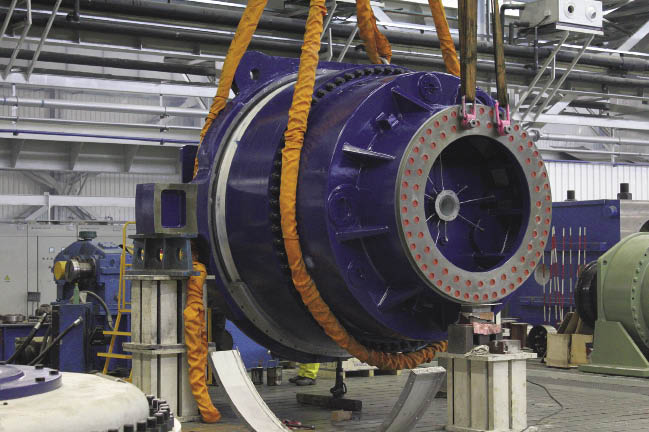

Wind turbine gearbox testing is designed to ensure the reliability and performance of gearboxes under operational stresses.

Our evaluation covers multiple criteria such as load capacity, efficiency, vibration analysis, thermal behavior, and durability under various environmental conditions. This includes compliance with global standards, minimizing downtime, and enhancing the lifespan of wind turbine components while optimizing maintenance strategies.

Furnace oil, also known as fuel oil, is commonly used in industrial heating applications, boilers, and furnaces to generate heat energy. Testing furnace oil is essential for ensuring efficient combustion, maintaining equipment integrity, and adhering to environmental regulations. Here are key reasons why testing furnace oil is necessary:

Regular testing of furnace oil is crucial for maintaining efficient and safe operations in industrial heating systems. It helps prevent equipment damage, reduce maintenance costs, optimize fuel usage, and ensure compliance with environmental standards.

During the heat treatment process, quenching oil is used to rapidly cool heated metal components, like steel and other alloys, so that the desired mechanical properties, like strength and hardness, can be achieved. Testing extinguishing oil is fundamental to guarantee the viability of the extinguishing system and to keep up with the quality and execution of treated metal parts.

Quenching oil must be tested on a regular basis to ensure the quality and dependability of heat-treated metal parts. It aids in defect prevention, extends the oil's service life, and ensures the quenching process' safety and effectiveness.